Mass Production

Metal“Sheet metal,” is a term that usually refers to metal sheets or plates. In the metal industry, it is usually refers to metal sheets made of materials such as steel, aluminium or copper. These metal sheets, can be of various thicknesses and specifications and are used in industrial applications, construction industry, automotive industry, shipbuilding and many other fields.

Materials:

Sheet metal is usually made from metal materials such as steel, aluminium, copper, stainless steel. The choice of material can vary depending on a number of criteria such as application, durability and cost factors.

Production Process:

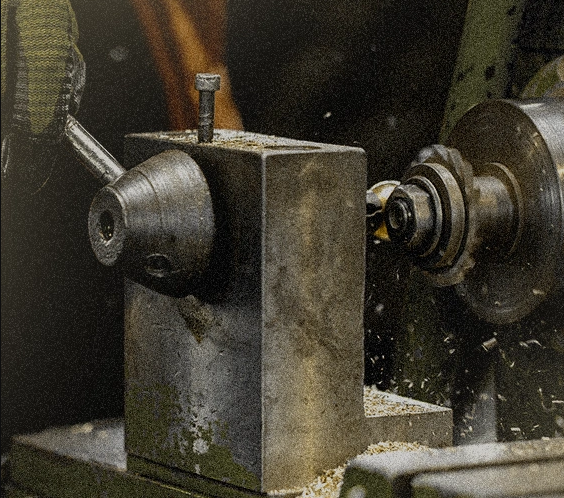

Sheet metal is produced by forming metal plates to the desired thickness and shape using various production processes such as rolling or pressing. The metal sheets are shaped by rolling machines or pressing equipment.

Areas of Use:

Sheet metal has a wide range of uses in many industries and sectors. For example, it is used in many areas such as roof coverings in the construction industry, vehicle body parts in the automotive industry, coating panels in white goods production.

Various Thicknesses and Sizes:

Sheet metal can be found in a wide variety of thicknesses and sizes. This means that it can be selected in accordance with specific application requirements.

Rustproofing and Coating:

Some types, such as stainless steel sheet metal, have stainless properties to increase their durability. They can also be subjected to special coating processes in some cases.

Sustainability:

Recycling metal can improve the sustainability of sheet metal. The use of recyclable metal can reduce environmental impacts and utilise natural resources more efficiently.

Sheet metal is used in many industries due to its advantages such as durability, strength and formability. is a widely preferred material. The use of this material, together with technological developments continuously evolve and diversify in accordance with industry needs.

Mould design is the design of moulds used for the mass production of products, usually from materials such as metal or plastic. refers to the design process of the mould or matrix. This design process involves the design of a predetermined product is carried out in order to ensure that it is produced in a form, size and material. Mould design is usually includes the following steps:

- Needs Analysis: The first step is to conduct an analysis on the needs and requirements of the part to be manufactured. This includes the dimensions, material, durability and other features of the part.

- Design Concepts: Based on the needs analysis, different design concepts are developed. These concepts include factors such as the shape, dimensions, material and production process of the product.

- CAD (Computer Aided Design) Modelling: Selected design concepts are digitally modelled using CAD software. This step involves the creation of a three-dimensional design of the product.

- Analysis and Optimisation: Analyses are performed on the CAD model and factors such as durability of the design, fluidity, temperature distribution are examined. If necessary, the design is optimised.

- Detailed Design: A detailed study is carried out on the selected design. In this step, each detail of the part, tolerances, assembly points and material selection are determined.

- Determination of the Production Process: Mould design involves determining the manufacturing process. This includes factors such as which material will be used, the mould manufacturing process and the equipment required for mould production.

- Prototype Production and Testing: A prototype of the design is produced and tested. This is important to evaluate how the design performs in real world conditions.

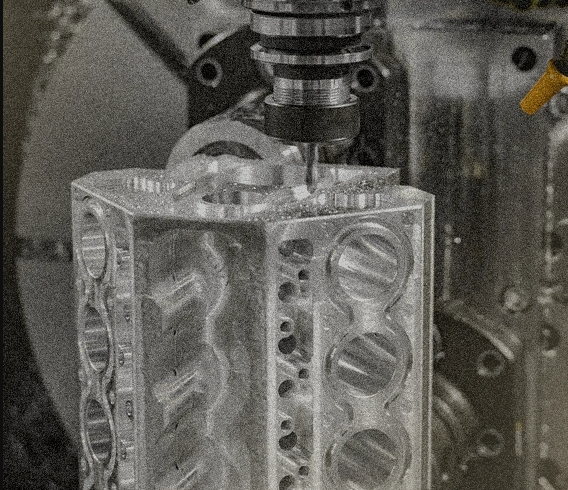

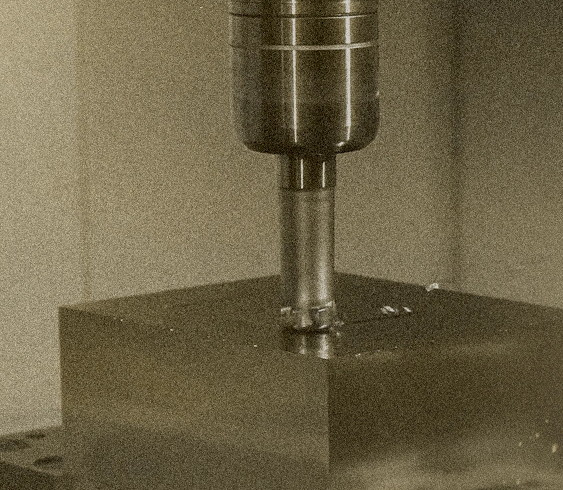

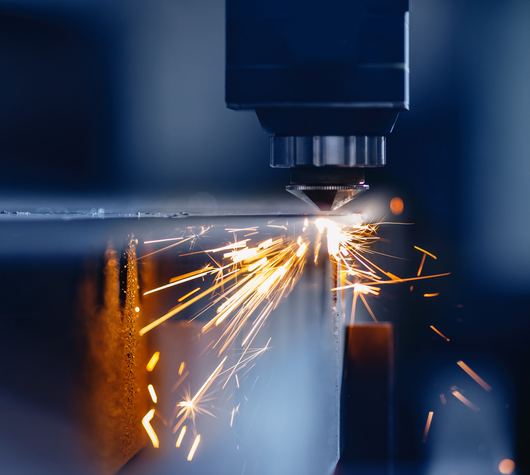

- Mould Production: After prototype testing, mould production is carried out according to the approved design. This is usually done using high precision manufacturing methods such as CNC (Computerised Numerical Control) machines or electrical discharge processes.

Mould design plays a critical role in industrial manufacturing processes and is essential for the quality, cost and production of products. has a great influence on the speed. A good mould design allows products to be manufactured more efficiently. production and marketing.